Post by greenbean on Aug 23, 2009 20:55:39 GMT -5

Alright,

Was a good weekend to do a couple of mods since I had 4 days off...so I did my Rokmen Hoplite full aluminum corners and a little tailgate mod that I saw on another member's rig. First the Corners!

If you have never did a set of corners and plan to at some point there are a few things you need to do:

1. Read a lot of write ups and the instructions 2-3 times

2. Make sure you have the tools you need. With a set of full corners you need a bunch of clamps to get the corners fitted correctly.

3. Allow for bumps in the road! ;D

First strip everything off the back half of the Jeep...Flares, Liscence plate holder, fuel port plastic thingy, and the tailgate. Also having the top down or off will make life much easier drilling and tightening bolts, clamping the corners etc,..

After I got all the stuff off the body I cleaned all the built up grime and dirt off...with some help from my littlest Jeeper! ;D

So with the Rokmen corners went to place the corners on the body for initial fitment and discovered that my Lite-Dot LED tailights are NOT the same size as the standard flush-mount LED's...Errrrrrr. Probably as much my fault for not asking about this...Standard LED hole is about 4.5" and the lite dots were slightly bigger...soooo, I took them off and decided to figure out the tailights later.

Using the fender flare bolts, lisence plate bolts, and tailgate hinge bolts allows you to get the corners up on the body and start adjusting things. Basically I got the coners on there and then started from front to back, clamping my way around the tub. The idea being to get all the fender flare, fuel port or other pre-existing body holes to line up with the holes pre-drilled in the corners. This was not an easy taskt on the Drivers side with a lot more holes to deal with lining them up took some serious cranking on the clamps to get the Drivers side corner pulled forward far enough for the holes to all line up.

Here you can see the various clamps I needed to get things to line up!

This fitment is the most critical part, get it right from the get go and you will have no worries, also you want these things fitting as tight as possible against the tub which makes them much more effective armor. Once the fitment is to your satisifaction, you start drilling holes for counter-sunk stainless hardware after center-punching the hole, first with a pilot bit, then a larger bit to get it the correct size.

Once you have the holes drilled, again working from the back tailgate edge to the front, put the couter-sunk hardware in, tightening them down as you go to get the best fit possible. One word of caution, there are about 3 spots where corner bolts go through double-wall on the tub, DO NOT over do the tightening on these as it will cause your Tub to deform where you don't want it to.

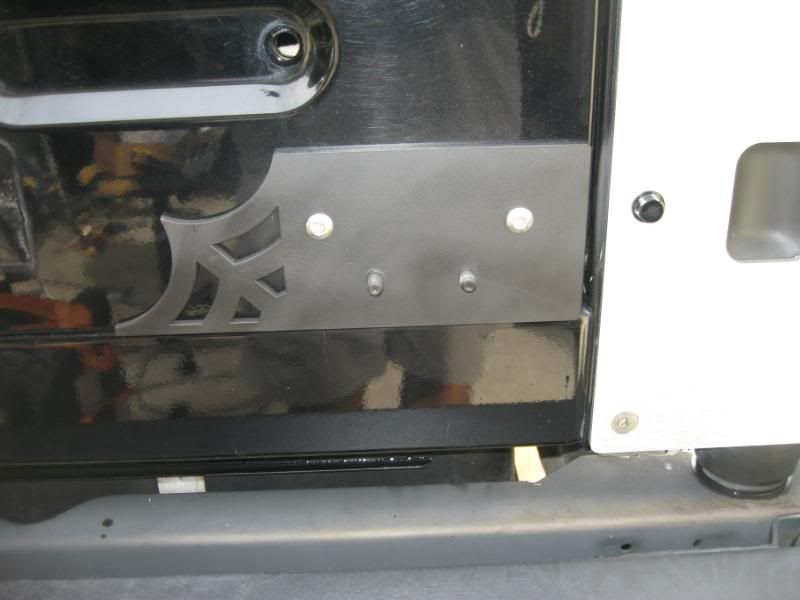

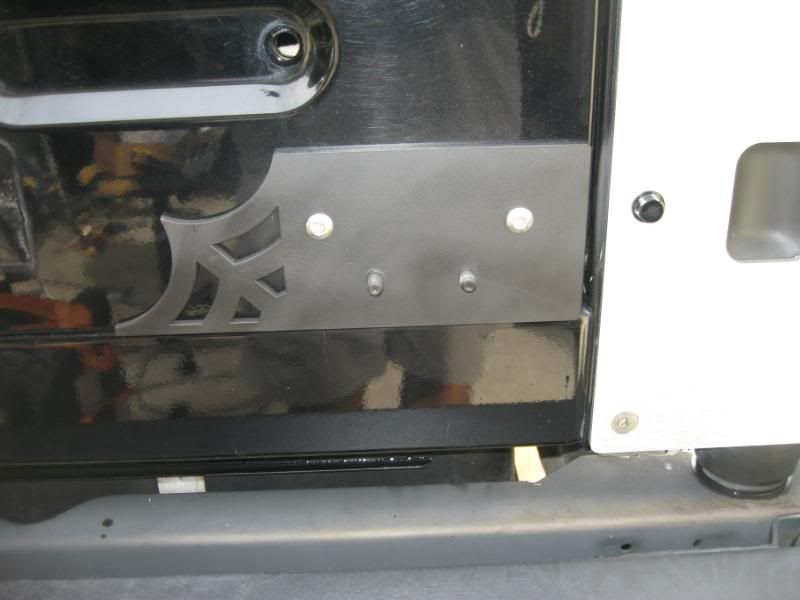

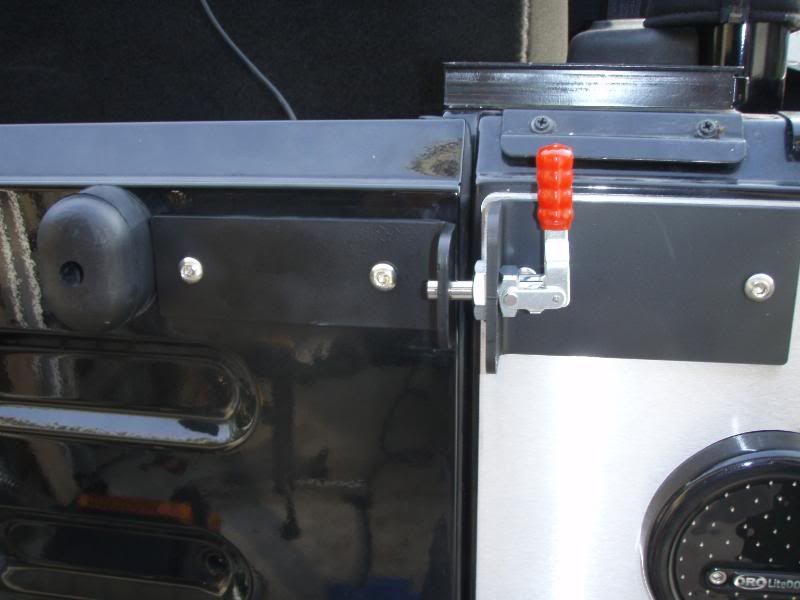

Some pics of the finished corners...I re-installed the Lite-Dots on top of the corners, they are not perfect but still fucntional.

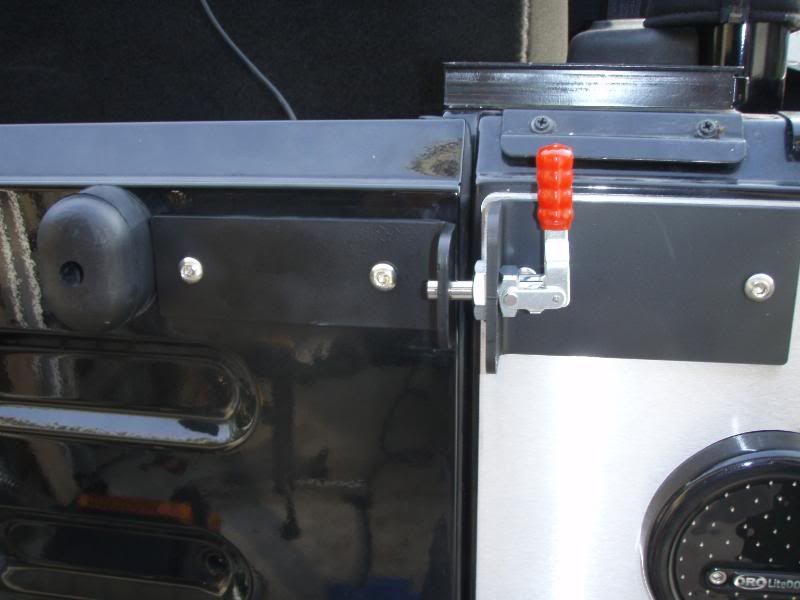

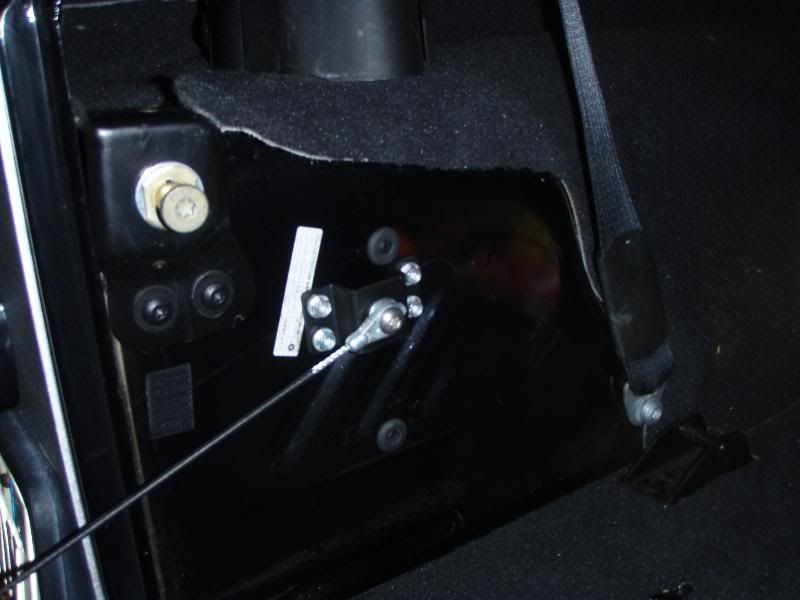

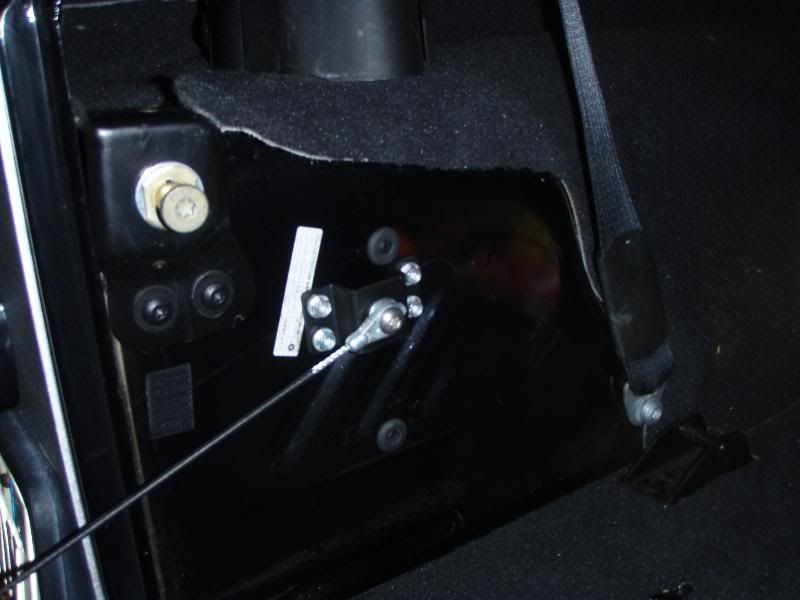

And second project for the day was this tailgate mod...

Till the next mod! ;D

Will

Was a good weekend to do a couple of mods since I had 4 days off...so I did my Rokmen Hoplite full aluminum corners and a little tailgate mod that I saw on another member's rig. First the Corners!

If you have never did a set of corners and plan to at some point there are a few things you need to do:

1. Read a lot of write ups and the instructions 2-3 times

2. Make sure you have the tools you need. With a set of full corners you need a bunch of clamps to get the corners fitted correctly.

3. Allow for bumps in the road! ;D

First strip everything off the back half of the Jeep...Flares, Liscence plate holder, fuel port plastic thingy, and the tailgate. Also having the top down or off will make life much easier drilling and tightening bolts, clamping the corners etc,..

After I got all the stuff off the body I cleaned all the built up grime and dirt off...with some help from my littlest Jeeper! ;D

So with the Rokmen corners went to place the corners on the body for initial fitment and discovered that my Lite-Dot LED tailights are NOT the same size as the standard flush-mount LED's...Errrrrrr. Probably as much my fault for not asking about this...Standard LED hole is about 4.5" and the lite dots were slightly bigger...soooo, I took them off and decided to figure out the tailights later.

Using the fender flare bolts, lisence plate bolts, and tailgate hinge bolts allows you to get the corners up on the body and start adjusting things. Basically I got the coners on there and then started from front to back, clamping my way around the tub. The idea being to get all the fender flare, fuel port or other pre-existing body holes to line up with the holes pre-drilled in the corners. This was not an easy taskt on the Drivers side with a lot more holes to deal with lining them up took some serious cranking on the clamps to get the Drivers side corner pulled forward far enough for the holes to all line up.

Here you can see the various clamps I needed to get things to line up!

This fitment is the most critical part, get it right from the get go and you will have no worries, also you want these things fitting as tight as possible against the tub which makes them much more effective armor. Once the fitment is to your satisifaction, you start drilling holes for counter-sunk stainless hardware after center-punching the hole, first with a pilot bit, then a larger bit to get it the correct size.

Once you have the holes drilled, again working from the back tailgate edge to the front, put the couter-sunk hardware in, tightening them down as you go to get the best fit possible. One word of caution, there are about 3 spots where corner bolts go through double-wall on the tub, DO NOT over do the tightening on these as it will cause your Tub to deform where you don't want it to.

Some pics of the finished corners...I re-installed the Lite-Dots on top of the corners, they are not perfect but still fucntional.

And second project for the day was this tailgate mod...

Till the next mod! ;D

Will